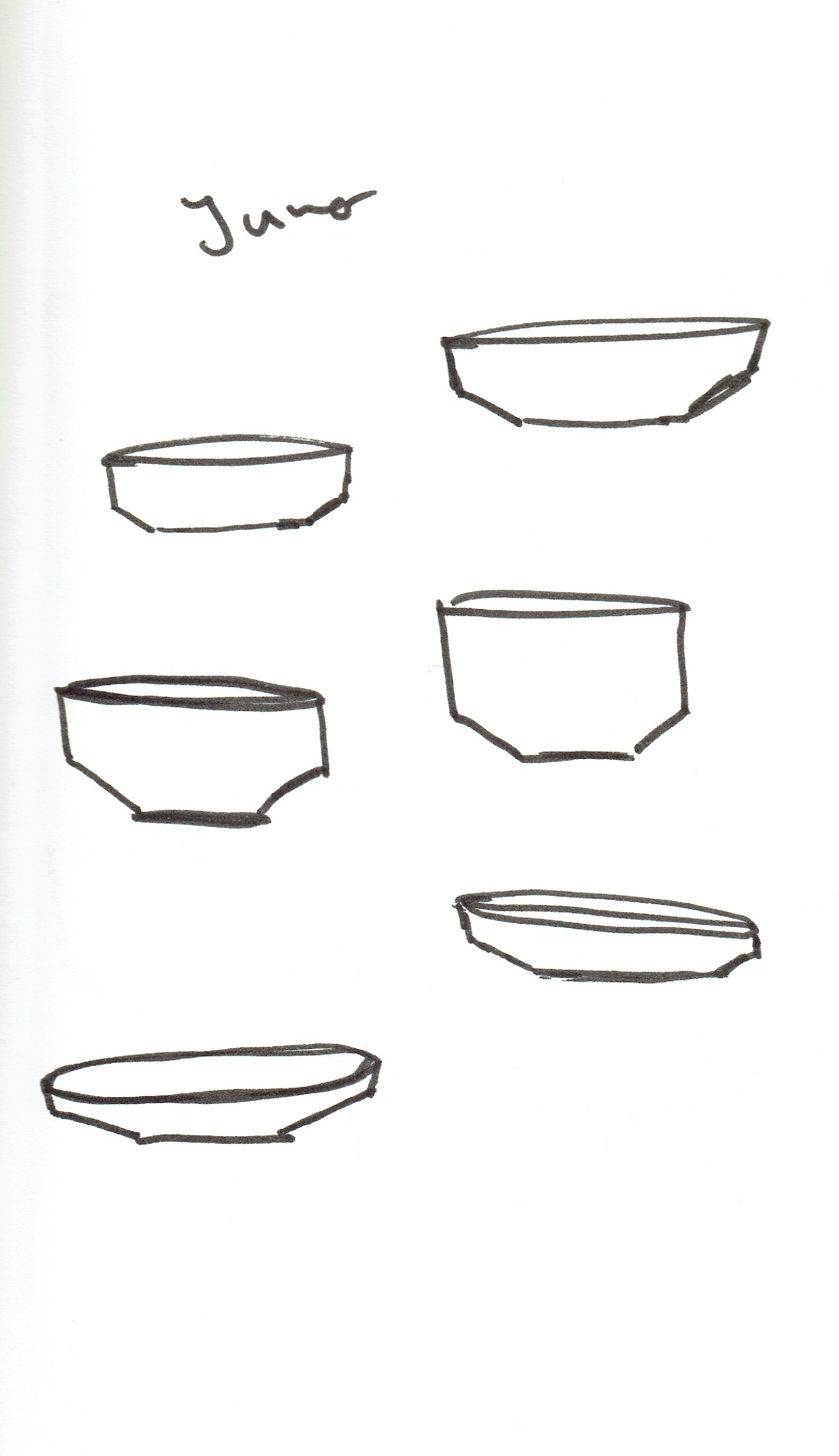

JUNO IN THE MAKING

Making of Juno, the latest shape and decor designed by Bodo Sperlein for German tableware manufacturer Dibbern. From the initial sketches of the shape to the first sample, each step was meticulously considered to design an aesthetically pleasing yet functional collection that could be used by everyone, including restaurants.

The process begins with sketching the prospective pieces for the collections. This is a long process, with many different sketches created of potential designs considering the material, the craftsmanship required and the desired look and functionality, before the final selection of 6 designs for the collection was made.

Once the designs have been created, the dimensions are explored using 3D Printing. Through a lot of trial and error, the necessary measurements are found in this way. The importance to Bodo was to design tableware that has a unique quality, therefore introducing the elevated base and architectural, soft curves.

After the dimensions have been decided, a mould is created in order to ensure consistency in the handmade pieces going forward. The Fine Bone China is poured into the mould and cast, followed by the fettling process, which removes unwanted parts of the cast in preparation of the next stage.

After the fettling comes the spinning, where the design is sculpted into the correct shape. Once the shape has been made, the paint is applied by hand and glazed, in order to give the piece its pure white colour. The piece then goes through the firing process, completing the process of manufacturing the Juno Collection in the traditional way in the German workshop.

As every piece of the Juno Collection is handcrafted, this process is repeated again and again to create each piece of the contemporary tableware you see today.